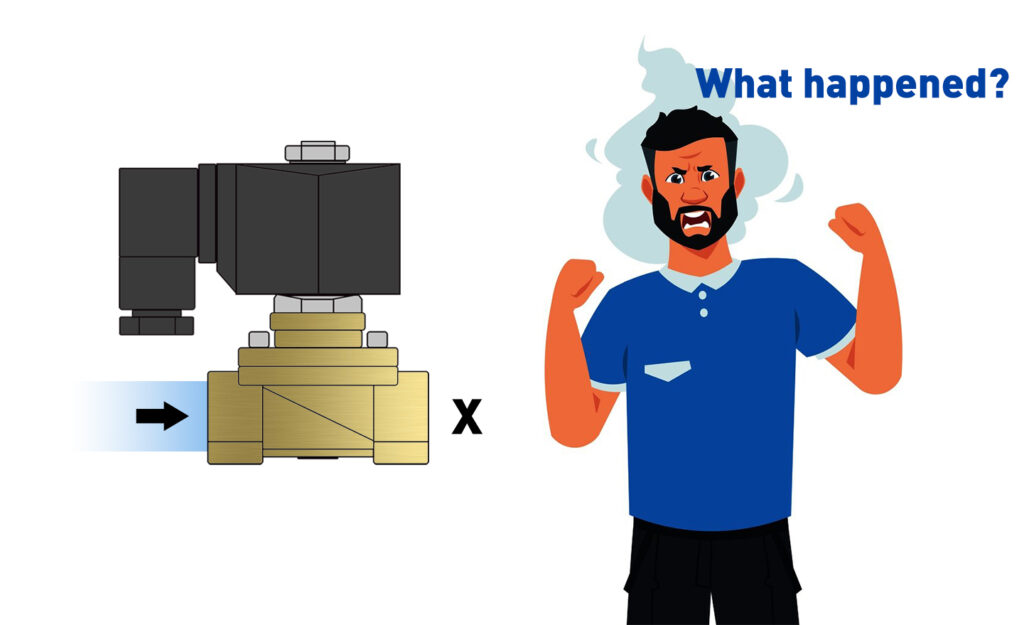

Solenoid valves find widespread use in a range of applications, from regulating water flow in residential plumbing to managing fuel flow in automobile engines. These valves operate by utilizing electromagnetic forces to manipulate a small plunger, either allowing or blocking the passage of fluid through the valve. However, similar to all mechanical components, solenoid valves can experience wear and tear over time. In this blog post, we will delve into the consequences of a malfunctioning solenoid valve.

Foremost, a defective solenoid valve can disrupt or entirely halt the operation of the system it belongs to. This is due to the valve’s inability to open or close correctly, impeding the fluid flow within the system. For instance, a washing machine’s malfunctioning solenoid valve may render it unable to fill with water, rendering it nonfunctional.

Another common indicator of a failing solenoid valve is leakage. When the valve can no longer form a proper seal, fluid may escape through the valve, leading to the formation of puddles around the valve or in its vicinity. This situation can become hazardous, particularly if the fluid in question is harmful, such as gasoline or chemical substances.

Furthermore, as a failing solenoid valve struggles with its operation, it may emit unusual sounds or vibrations. This can be a consequence of the plunger inside the valve getting stuck or failing to move as intended, resulting in vibrations or a buzzing noise.

If you suspect that a solenoid valve within one of your systems is malfunctioning, it is crucial to address the issue promptly. Continuing to operate a system with a faulty valve can result in more severe problems, including damage to other components or even complete system failure.

To diagnose a faulty solenoid valve, it is advisable to seek the expertise of a professional or a qualified technician. They can conduct assessments to determine the valve’s functionality and, if necessary, replace it.

In summary, a malfunctioning solenoid valve can lead to various complications, including system malfunctions, leaks, and unusual noises or vibrations. Should you suspect a solenoid valve in one of your systems is experiencing issues, taking prompt action is essential to prevent the development of more serious problems.