When you require a valve, you’re presented with several options, each tailored to address specific issues in distinct ways. Making the right selection based on your precise requirements can lead to cost savings and time efficiency.

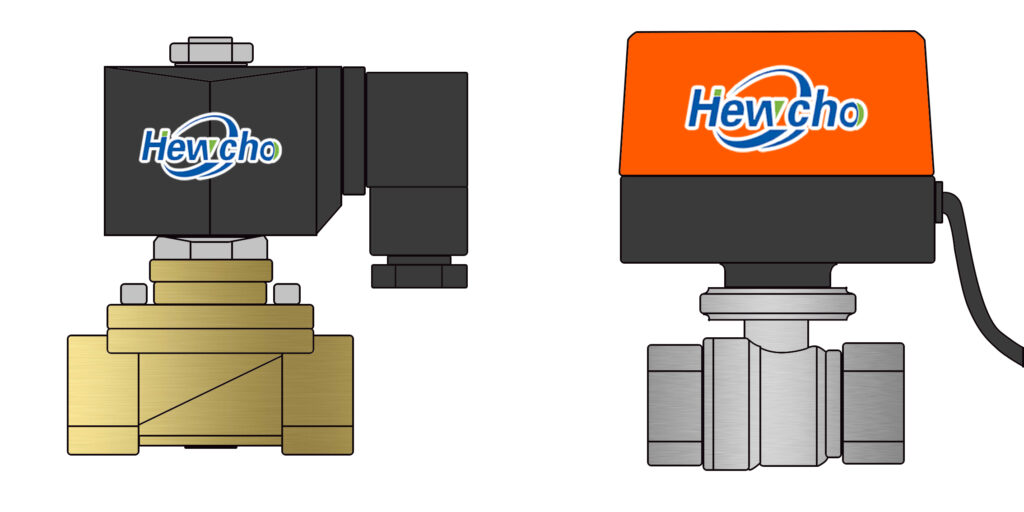

We’ve noticed that many of our customers often inquire about the distinctions between motorized ball valves and solenoid valves, as well as the considerations that drive their choice.

This article is designed to elucidate the disparities between these two valve types and outline the advantages and disadvantages associated with each.

WHY USE A VALVE?

When it comes to controlling the flow of fluids, air, or gases within a system, valves play an indispensable role. Valves are pivotal components found in a spectrum of applications, ranging from everyday household tools like sprinkler systems to intricate mechanical systems, including the spacecraft of esteemed organizations like NASA and SpaceX. Remarkably, many individuals use valves routinely, such as those integrated into garden hoses, often without recognizing their presence.

Motorized valves step in to manage unmanned operations. They operate much like manual ball valves but rely on electric motors for functions such as opening, closing, dosing, and distribution. Operators can control these valves through automated systems, whether within the facility or remotely. Understanding the distinction between a motorized ball valve and a solenoid valve can enhance operational efficiency by selecting the most suitable valve for your specific needs.

WHAT IS A SOLENOID VALVE?

A solenoid valve operates in response to an electric current, harnessing the power of an electromagnet created by a wire coil known as a solenoid. Within the framework of a valve system, the solenoid assumes the role of regulating the flow of current through the valve. In its default state, a solenoid valve, typically classified as “normally closed,” remains closed as a plunger obstructs the valve’s opening. To initiate valve opening, a simple electric current is passed through the solenoid, generating a magnetic field. This magnetic force elevates the plunger, consequently opening the valve.

Conversely, there exists the counterpart known as a “normally open” valve, which remains in the open position until an electric current is applied to close it.

Manufacturers leverage solenoids to exercise precise control over the distribution, release, or mixing of various substances, whether they are fluids, air, or gases. This adaptability enables businesses to employ solenoid valves across a multitude of applications.

One notable advantage of solenoid valves is their minimal power consumption, coupled with their reputation for reliability, durability, and compact design.

WHAT IS A MOTORIZED BALL VALVE?

Motorized ball valves employ electrically powered motors to rotate a ball featuring a central aperture, thereby regulating the flow of substances. When the aperture aligns with the flow, the valve is fully open, and when it turns perpendicular to the flow, the valve closes. Notably, many electric ball valves do not require a continuous power supply to maintain their position, in contrast to solenoid valves. Furthermore, certain electrically actuated ball valves offer the option of manual operation for opening and closing.

Ball valves are particularly effective in scenarios involving the management of substantial flow volumes. For instance, airports utilize them for de-icing aircraft, greenhouse operators rely on them for irrigating greenhouses, and farmers employ them to irrigate extensive farmlands. Additionally, buildings equipped with fire suppression systems depend on ball valves for the precise control of opening and closing sprinkler heads.

Motorized ball valves offer a means to regulate the passage of liquids, gases, or air through electric controls, with some systems featuring multiple valves to oversee extensive and complex systems.

TYPES OF VALVES

The decision between a motorized ball valve and a solenoid valve represents just the initial consideration. Within each of these valve categories, you’ll encounter various subtypes, each suited to specific scenarios and applications.

Types of Solenoid Valves

There are three prevalent types of solenoid valves, each designed to perform specific functions related to fluid movement:

- Two-way solenoid valve: This variety of valve comprises an inlet and an outlet, both connected to the fluid source. Two-way solenoid valves offer a binary choice – they can either open or close. These valves close to halt the flow of fluid and open to allow it to pass through.

- Three-way solenoid valve: This type of valve incorporates three ports. It offers three distinct control settings: normally closed, normally open, and a general type. Three-way valves provide the capability to direct the flow through different ports as required.

- Four-way solenoid valve: This valve functions akin to a double-acting cylinder and features one or two exhaust ports, two cylinder ports, a pressure port, and several connectors in its configuration. It serves specific applications that demand this unique combination of ports and functions.

Types of Motorized Valve

There are three primary types of motorized valves designed to facilitate fluid movement within pipelines:

- Quarter-turn motorized valve: This category of valve employs a 90° (one-quarter turn) motion to operate, allowing for the precise opening and closing of a port. These actuators collaborate with various valve types, including ball valves, plugs, chokes, and butterfly valves, to regulate the flow of fluid with precision.

- Multi-turn motorized valve: These actuators are engineered to handle valves with more intricate requirements, utilizing tools such as balls, gates, or other mechanisms to effectuate the opening and closing of valves.

- Linear-motorized valve: Linear valves are compatible with control valves or diaphragm valves, enabling them to facilitate the movement of fluids within the system.

PROS AND CONS OF SOLENOID VALVES

Solenoid valves offer numerous advantages with a few accompanying limitations, underscoring the importance of selecting the appropriate valve type for specific applications.

Solenoid valves exhibit rapid response times, capable of operating with both AC and DC currents, enabling near-instantaneous opening or closing of flow channels within the system.

Thanks to their straightforward design, solenoid valves boast low power consumption. They require electrical input solely for transitioning and maintaining the “on” position, without any power consumption to hold their “normally open” or “normally closed” state. However, it’s essential to note that continuous power is necessary to maintain a position, which can lead to heat buildup in the coils, potentially causing valve damage if left in the “on” position for extended durations.

Solenoid valves present a cost-effective option, suitable for many systems due to their ease of installation and maintenance. Unlike their alternative, the ball valve, solenoid valves can be refurbished by replacing worn-out internal components like coils.

While they possess high-cycle capacities, solenoid valves have limitations concerning back pressure and inlet pressure due to distinct internal configurations in the flow path. Additionally, pressure differentials necessitate pilot designs, and if a higher flow rate is required, a motorized ball valve may be a more suitable choice. It’s worth mentioning that solenoid valves lack manual overrides, potentially leading to water hammer issues resulting from rapid closure.

Most solenoid valves operate using an internal diaphragm and plunger mechanism, which can be vulnerable to problems when particles are present in the line. Debris can prevent proper sealing, resulting in leakage. Although most valves can be serviced, this is an area where ball valves excel, as they don’t rely on a diaphragm for sealing and can handle a more significant degree of particulate matter and debris.

PROS AND CONS OF MOTORIZED BALL VALVES

Motorized ball valves, much like their counterparts, come with their own set of advantages and disadvantages.

One notable advantage is their capacity to maintain high flow rates even in the presence of a pressure drop. Because they lack a diaphragm, they boast a higher Cv value, indicating a superior flow rate when compared to solenoid valves of the same size.

Similar to solenoid valves, motorized ball valves offer an economical and relatively straightforward installation process. They seamlessly integrate into automation systems through a variety of devices, including personal computers and even Raspberry Pis. Moreover, the total operational cost of motorized ball valves is lower than that of solenoid valves since they do not require continuous power to maintain their position. This characteristic not only reduces operating expenses but also mitigates the risk of burnout, a common issue with solenoids.

However, motorized ball valves do have some drawbacks. They operate slightly slower than solenoid valves, although this reduced speed may be advantageous for systems prone to the water hammer effect, as it prevents abrupt and sudden flow stoppages.

Another drawback involves potential wear and tear within the ball valve itself. Suspended particles traveling through the system can lead to wear or jamming of the ball. While motorized ball valves are generally more resilient to regular wear and tear compared to solenoid valves, this factor should still be considered.

In the event of internal component damage, servicing motorized ball valves can prove more challenging. The precision machining of the ball to fit within the system means that damage to the ball may render the valve unusable, as it cannot be easily replaced—a contrast to solenoid valves, which often offer the option of rebuilding.

FINAL THOUGHTS

Ultimately, the choice of valve type hinges on a clear understanding of your specific requirements and the purpose behind needing a valve. Should you require further clarification or guidance in selecting the ideal valves for your project, our team of valve experts is readily accessible via phone or chat on Electricsolenoidvalves.com. We are here to assist you in making the most informed and suitable valve selection for your needs.