Industrial valve

What type of Industrial valves are you looking for?

HEWCHO is an Industrial valve manufacturer of solenoid valve, pneumatic angle seat valve, ball valve, plastic valve and accessories.

Our Factory in China had ISO9001 and CE certificate. Our products have been sold worldwide for a wide range of applications in water, air, gas, oil and other field pipeline systems.

Plastic Valves

Accessories of Valve

Customization

REQUEST A QUOTE FOR MORE DETAILS

The Guide of Industrial Valves

Valve types, sizes, application and more

What Are Industrial Valves?

Industrial valves are specialized mechanical devices designed to control the flow of fluids—be it liquid, gas, or a mixture of both—within a piping system. These valves operate by opening, closing, or partially obstructing passageways to achieve optimal flow characteristics. By manipulating the valve mechanism, one can precisely regulate flow rates, pressure, and direction. In industrial settings, they are crucial for system efficiency and safety, used in various applications such as in solenoid valves for fluid automation, ball valves for flow isolation, and pneumatic angle seat valves for high-temperature operations.

Understanding the mechanics and functionalities of industrial valves is indispensable for effective usage and cost-saving. Knowledge about the correct valve type for specific applications can prevent operational failures and reduce unnecessary system downtimes. Moreover, a well-informed choice in valves will also contribute to the longevity of the entire piping system. By focusing on key factors such as the material of construction, flow coefficients, and compatibility with the existing system, users can avoid potential losses and enhance operational efficiency.

Type of Valves?

Industrial Solenoid Valves

Industrial Plastic Valves

Industrial Angel Valves

Industrial Ball Valves

Accessories

Valves are integral components of any piping system, with each having its unique purpose. To put it succinctly, there are four main functions that industrial valves serve. Although some might perform multiple roles, they are typically optimized for one or two primary functions.

- Initiation and Termination: These valves either permit the flow of media or block it, ensuring it doesn’t pass through.

- Directional Flow Management: These valves are responsible for steering the flow of the media. They are often multidirectional and possess multiple exit points or ports. This design ensures the media can be channeled in various paths.

- Regulation of Pressure and Flow: By modulating their opening and closing actions, these valves can fine-tune or sustain the flow and pressure inside the piping system.

- Throttling: Certain valves have the capability to open partially, enabling a calibrated amount of media to pass through.

Part of Valves

Industrial Solenoid Valve

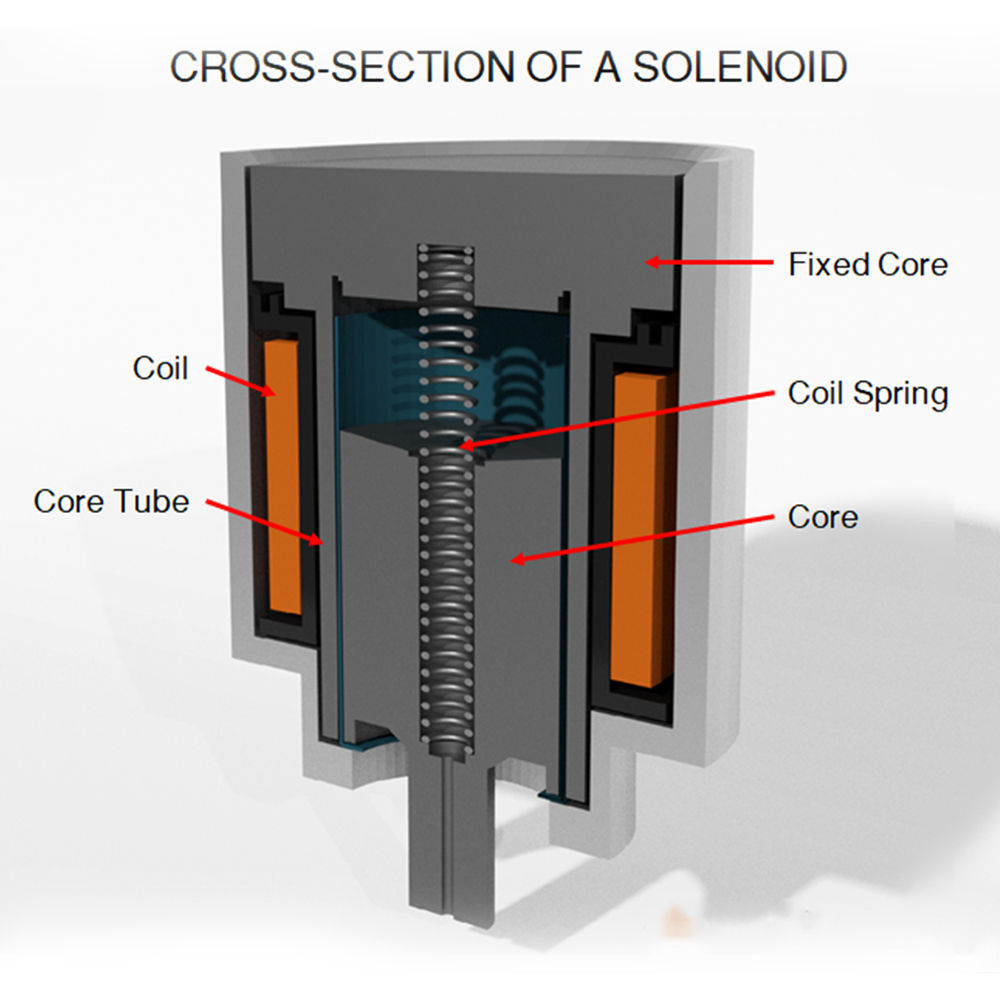

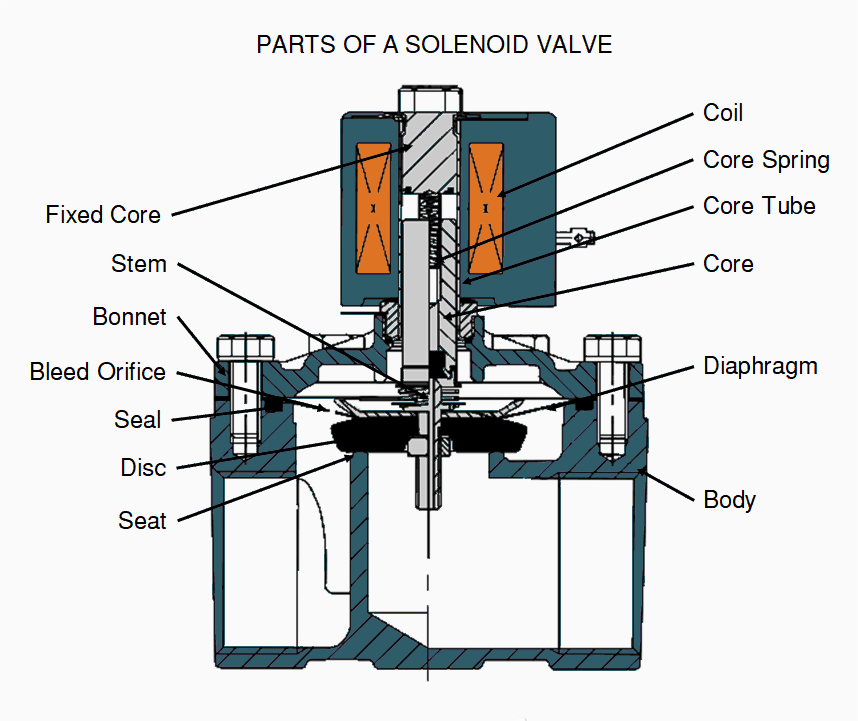

A solenoid valve can be broadly divided into two primary components: the solenoid and the valve body. The solenoid is merely one kind among a range of actuators, including manual, pneumatic, hydraulic, and others. The specific parts of a solenoid can differ based on the intended action. Conversely, while the components of the valve body remain consistent across different valves, their design and material composition can vary. Here’s a rundown of the basic elements of both the solenoid and the valve body.

Coil Essential to the solenoid, the coil is formed by an insulated copper wire wound snugly around a core tube. This component is pivotal in creating a magnetic field upon electrical activation.

Core (or Plunger/Armature) This movable section of the solenoid, made of easily magnetizable ferromagnetic metal, responds to the magnetic field generated by the coil, enabling the valve to open or close.

Core Spring Ensuring the core returns to its default state once the magnetic influence ceases, this spring’s design can differ based on the valve’s functionality. Some valve designs, like the latching type, might forgo springs altogether.

Core Tube Acting as the coil’s foundation, this component not only hosts the coil but also amplifies the magnetic flux produced by the coil, thanks to its soft magnetic core.

Fixed Core Located at the core tube’s closed end, this part, made of soft magnetic metal, further optimizes the magnetic flux.

Diaphragm This flexible barrier ensures the solenoid remains isolated from the fluid, effectively managing fluid pressure.

Stem Connected to the core or plunger, the stem is pivotal in valve activation, moving in tandem with the core’s magnetic attraction.

Disc Acting as the valve’s gatekeeper, the disc stops fluid flow when the valve is shut. Some designs might employ bellows, diaphragms, or pinch devices instead. Often, it’s crafted from materials resistant to corrosion, such as PTFE or stainless steel.

Seat Typically made of materials that resist corrosion, the seat connects with the disc to halt the valve. Some valve designs might exclude the seat.

Seal Acting as a protective barrier, the seal prevents fluid from interacting with the solenoid assembly and the environment. Materials like PTFE, FKM, NBR, and EPDM are commonly used based on the application.

Bonnet Positioned atop the valve body, the bonnet houses the core tube and stem that penetrate into the valve.

Body The valve’s primary structure, the body contains the diaphragm, disc, seat, and the fluid ports.

Bleed Orifice Featured in some solenoid valves, this component aids in utilizing line pressure to operate the valve, particularly in indirect or semi-direct acting valves.

Pilot Channel Present in indirect acting solenoid valves, this channel directs fluid from atop the diaphragm to the valve’s downstream side.

Industrial Pneumatic Angle Seat Valves

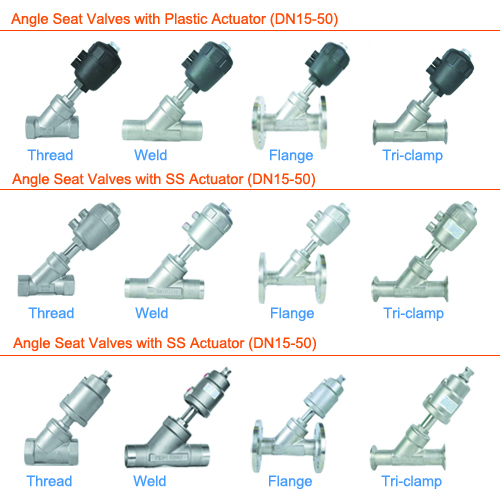

Angle seat valves are versatile 2-way, 2-position pneumatic piston valves equipped with a pneumatic piston actuator that imparts linear motion to unseat the seal. Due to the strategic positioning of the seat at an angle, they offer minimal flow disruption when in the open position, thus ensuring exceptional flow and minimal pressure loss. These valves find application in the control of various substances, including liquids, gases, vapors, vacuum, and even corrosive fluids. Angle seat valves are well-suited for operations in high-temperature and high-viscosity environments, even when there is zero differential pressure. Their robust construction makes them an ideal choice for demanding applications, and they boast an impressive cycle life.

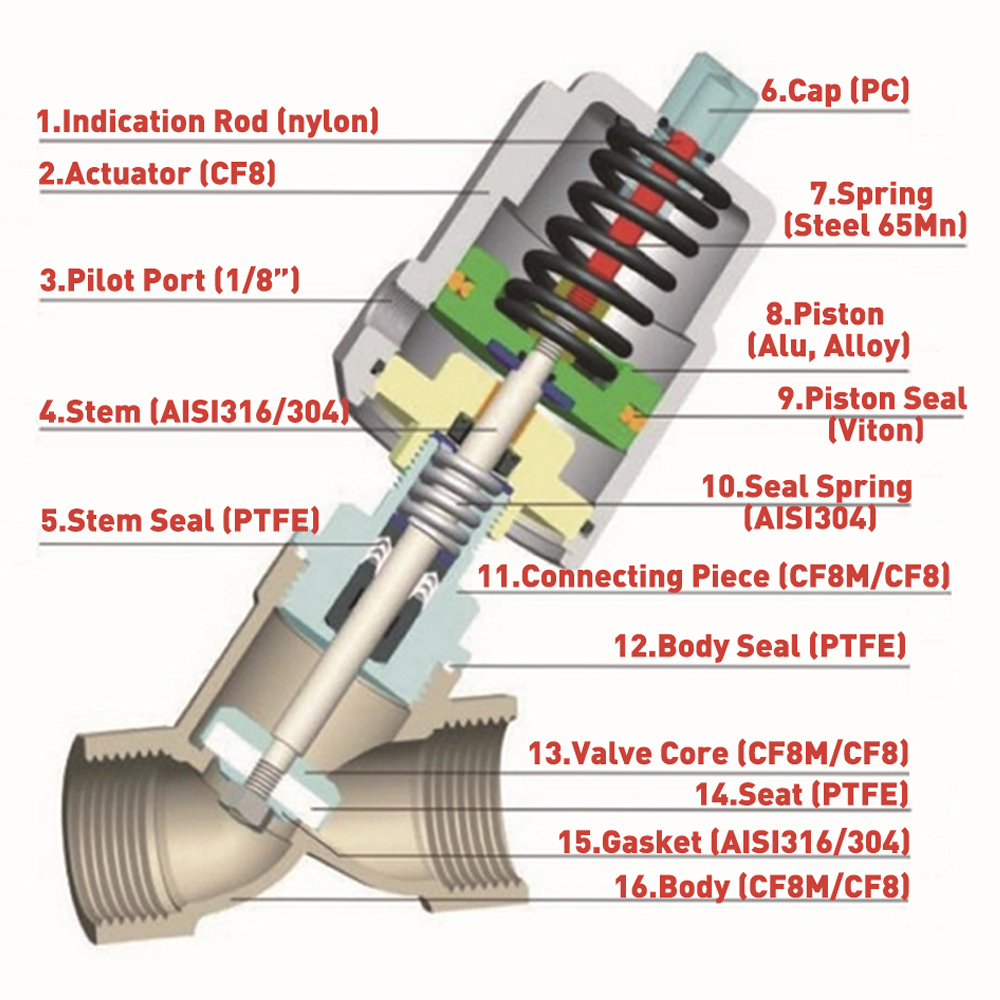

Indication Rod: Nylon

Actuator: CF8

Pilot Port: 1/8″

Stem: AISI 316 OR 304

Stem seal: PTFE

Cap: PC

Spring: Steel 65Mn

Piston: Alu, Alloy

Piston Seal: Viton

Seal Spring: AISI304

Connecting Piece: CF8M OR CF8

Body Seal: PTFE

Valve Core: CF8M OR CF8

Seat: PTFE

Gasket: AISI316 OR 304

Body: CF8M OR CF8

Industrial Ball Valves

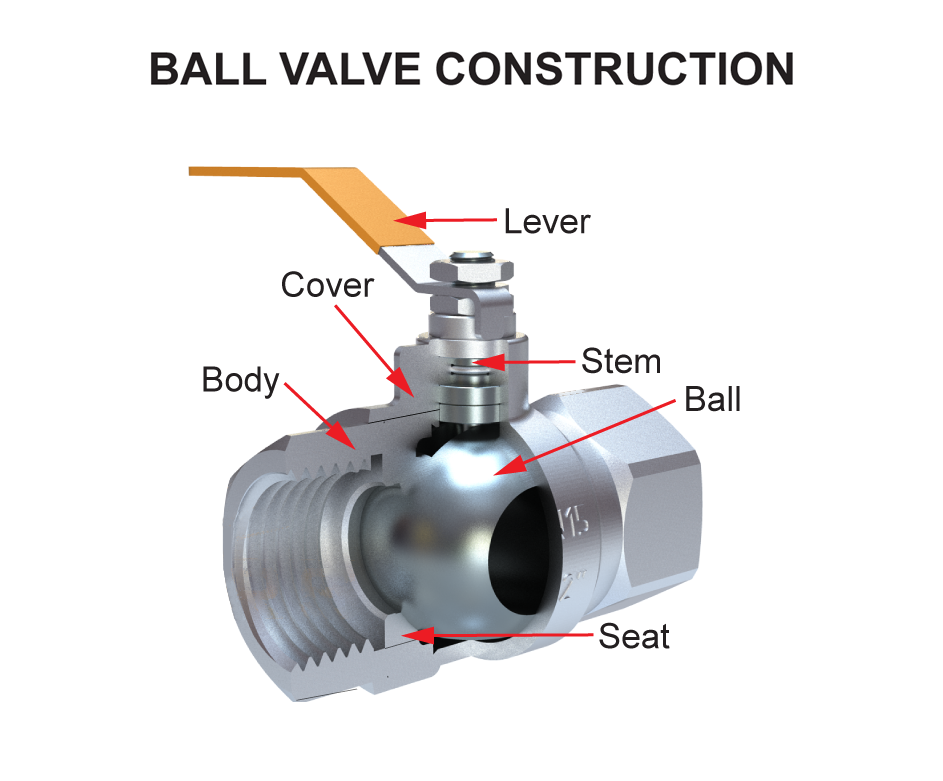

A ball valve comprises two essential components: a stem and a rotatable ball. The stem serves as the link between the actuator and the ball, enabling the ball’s rotation. The valve’s body typically takes on a rectangular shape, with an enlarged rectangular section at the end where the ball is situated. The stem also plays a crucial role in positioning the ball.

The stem of the ball valve establishes the connection between the ball and the external control mechanism. In manual valves, a lever or handle is employed to manipulate the stem, whereas automatic variants harness electric, pneumatic, or hydraulic power for this purpose.

Furthermore, the valve’s bonnet serves as a protective enclosure, ensuring a tight seal between the valve’s body and the ball. In addition to safeguarding the ball, the bonnet also covers the ball’s opening.

A ball valve is composed of multiple intricate components. If you wish to delve deeper into an exploration of these individual parts, please continue reading this article.

Valve Body

The valve casing represents a crucial element of a ball valve, acting as the housing for all other components. It plays a pivotal role in governing the movement of the various parts within a pipeline system. This casing serves as the primary structure of the valve and can be constructed from a variety of materials. Cast casings are commonly used, while high-pressure valves make use of forged casings.

Ball

An essential facet of a ball valve comprises a rotating sphere, a stem, a seating mechanism, and a control apparatus. The sphere connects to the control mechanism via a shaft. This hollow sphere rotates to manage the flow within the valve and is the central component of the ball valve.

Stem

A ball valve, as a type of mechanical valve, features a control rod connected to an initial shaft. This shaft undergoes rotation in response to an actuating force. The ball valve’s control rod links the sphere to an external control mechanism. In the case of manual ball valves, a handle or lever is employed to turn the control rod. The control rod is coupled with the handle, facilitating the rotation of the sphere.

Seats

Valve seating arrangements can be fabricated from diverse materials, including ceramics, metals, or combinations thereof. Ball valve seats exhibit various characteristics. The inner seat of a ball valve is typically crafted from a range of materials, with innovative substances being used for these seats. For instance, synthetic resins may serve as seat materials, offering comparable attributes to PTFE in terms of friction, creep resistance, and monomer permeation resistance.

Power Source

Ball valves come in two fundamental types: pneumatic and electric. Pneumatic ball valves rely on compressed air as their energy source, making them ideal for applications necessitating durability and rapid cycling. Electric actuators, also known as motorized ball valves, harness electricity. Hydraulic ball valves, on the other hand, utilize pressurized fluid as their energy source, offering elevated torque and cycle rates, albeit with less durability compared to pneumatic valves.

Packing

Within a ball valve, three primary components are at play: the valve casing, the control rod, and the sealing mechanism. The sealing mechanism encompasses the stem and is positioned around it in the valve to prevent any medium from escaping. This mechanism serves as the essential seal, effectively averting any leakage within the valve.

Bonnet

The top cover of a ball valve functions as a cap that encloses the valve casing’s opening. It additionally serves as the secondary pressure boundary for the valve. The top cover is secured to the casing using bolts or screws. This cap securely holds the ball and control rod assembly in place and enables the adjustment of packing compression.

Valve Application

How do they work?

Solenoid valves are devices used to control the flow of fluids by either blocking or permitting it through electrical activation or deactivation. These valves employ an electromagnet as the actuator, which, when powered, generates a magnetic field that attracts a plunger or pivoted armature, overcoming the resistance of a spring.

A ball valve is categorized as a quarter-turn shut-off or isolation valve used for regulating the flow of liquids or gases. It does so by using a spherical ball with a central borehole that is secured within the valve body by two identical seat seals. To operate the valve, it is rotated 90°, which results in either opening or closing the valve.

Angle seat valves are pneumatically operated piston valves designed with a 2/2-way configuration. The piston actuator delivers linear motion to raise the seal from its seat. Due to the seat’s angled positioning, the flow remains largely unobstructed when the valve is open, ensuring high flow rates and minimal pressure drop.

Consideration When Buying

When purchasing industrial valves, several key factors demand consideration:

Valve Purpose: Begin by clarifying the valve’s intended function. Is it for throttling, control, or start-stop operations?

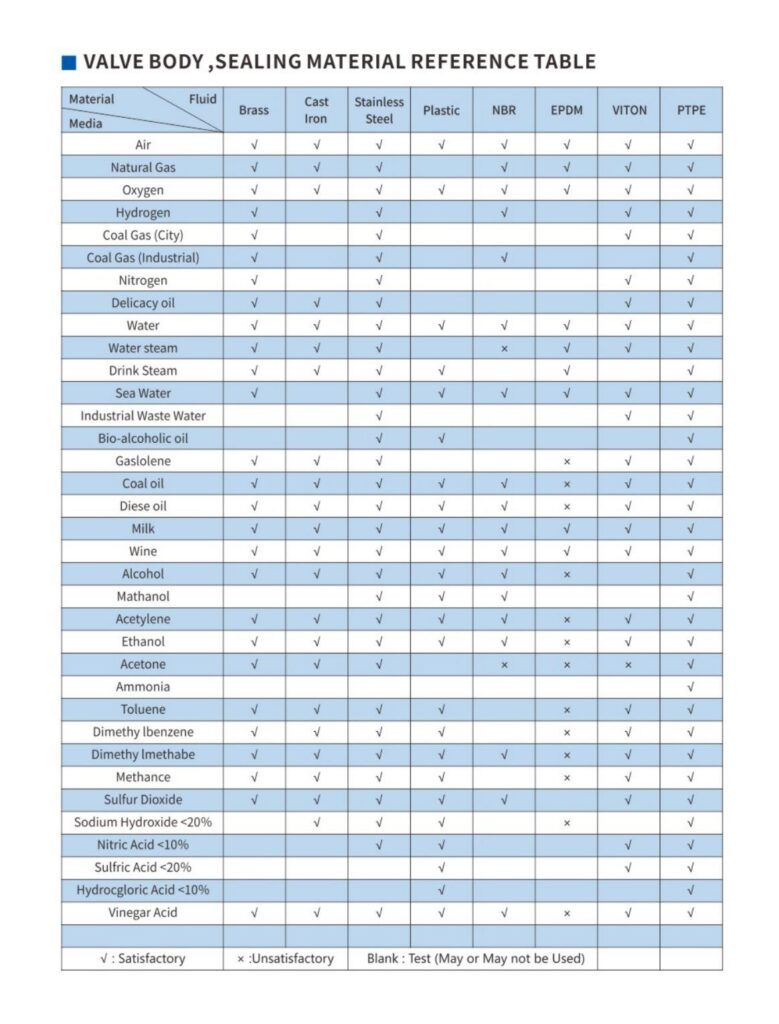

Media Compatibility: The nature of the substances passing through the valve significantly impacts its longevity. Using the wrong material can lead to valve damage. Some media are corrosive, while others are abrasive. It’s vital to understand how the valve material interacts with the specific media, including factors like pressure levels and temperature.

Actuation: Choosing the appropriate actuation method is crucial. For larger valves in process pipelines, manual operation may not be suitable. Pneumatic or automated valves are often the preferred choice.

Construction Material: The valve’s body material must align with the nature of the media it will handle. Corrosive media requires corrosion-resistant materials, while high-pressure applications necessitate alloys that can withstand elevated temperatures and pressures.

Valve Type: Consider the valve type that best matches your needs. Certain actuators are more compatible with specific valve types. For instance, ball valves, with their quarter-turn movement, pair well with rotary or quarter-turn actuators.

Valve Functions: Valves serve different functions, including shut-off, flow diversion, pressure relief, flow mixing, and flow adjustment. Understanding the specific role your valve should perform is essential.

Pipe Compatibility: The valve’s diameter should match that of the pipes to withstand high pressure effectively. Mismatched sizes can lead to bending and subsequent leakage, both internally and externally.

End Connections: Ensure compatibility between the valve’s end connections and the pipe. For instance, if the pipe uses a threaded connection, opting for a flanged end valve is not ideal.

Adherence to Industry Standards: Valves are subject to industry standards, encompassing materials, end connections, and safety regulations. It’s crucial that valves meet these stringent standards set by international bodies to ensure safety and proper installation.

GET A FREE QUOTE

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

+86 153 1452 4332

info@hewchovalve.com